Product Center

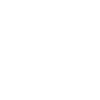

LED circuit board

Our company specializes in producing single, double, and multilayer circuit boards. We also provide SMT chip processing and FMT stencil making services according to customer requirements, offering one-stop component procurement. The company has professional workshops for board pressing, PCB production, photolithography, tin spraying, and electroplating. We possess industry-leading copper-clad laminate pressing technology and exquisite PCB production processes, achieving complete independent R&D.

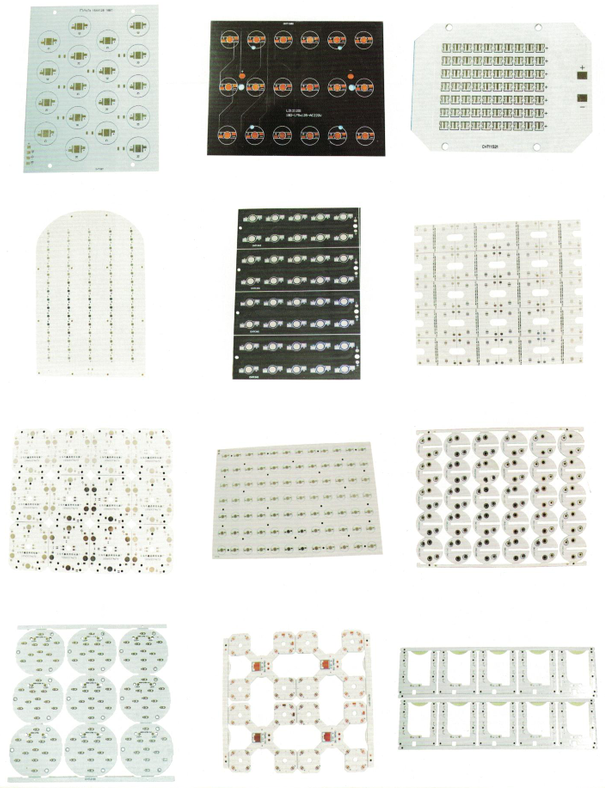

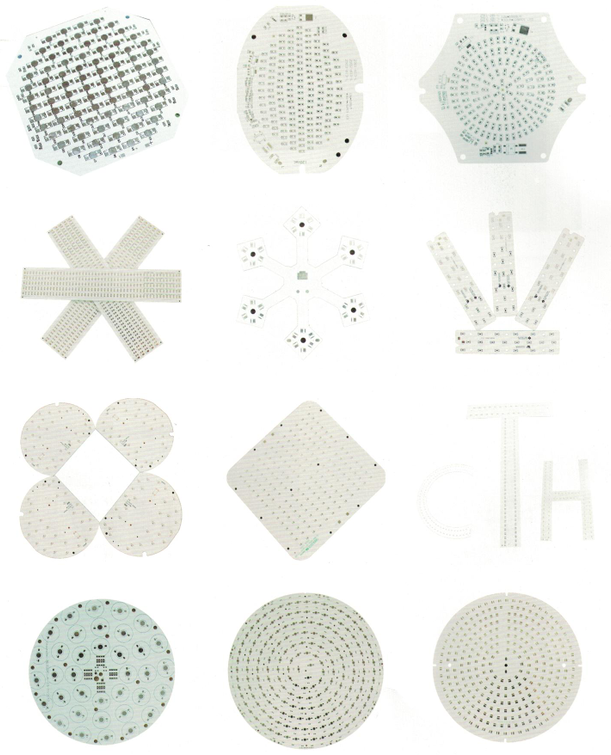

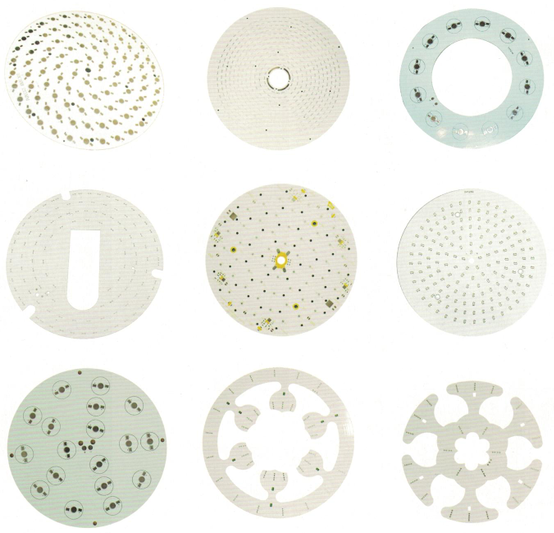

Series products: LED circuit board

- Product Description

-

LED Circuit Board Company Profile

Our company specializes in the production of single-sided, double-sided, and multilayer circuit boards. We also undertake SMT chip mounting and FMT stencil making services according to customer requirements, providing one-stop component procurement for our clients. The company has professional workshops for board pressing, PCB production, photolithography, tin spraying, and electroplating. We possess industry-leading copper-clad laminate pressing technology and exquisite PCB production processes, achieving complete independent R&D.

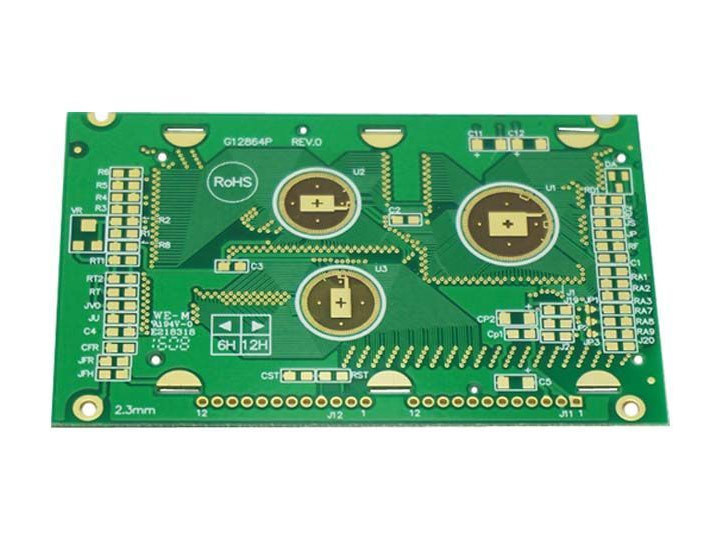

The company adheres to the quality policy of "reliable quality, continuous improvement," actively promoting the ISO9002 quality system. We have fully introduced advanced domestic and international circuit board production equipment and electronic mounting equipment. We have a strong, experienced, and innovative PCB elite team. Our factory covers an area of over 10,000 square meters, with an annual output exceeding 2,000,000 square meters.

Products are UL certified, meet EU RoHS directive requirements, and performance reaches IPC and MIL standards; widely exported to countries and regions including the Americas, Europe, Russia, Singapore, and South Korea; widely used in communications, computers, LED lighting, instrumentation, automotive electronics, medical devices, aerospace and military, power supply, detection and control systems, and general consumer electronics.

Workshop Environment

Main Products

Product Applications

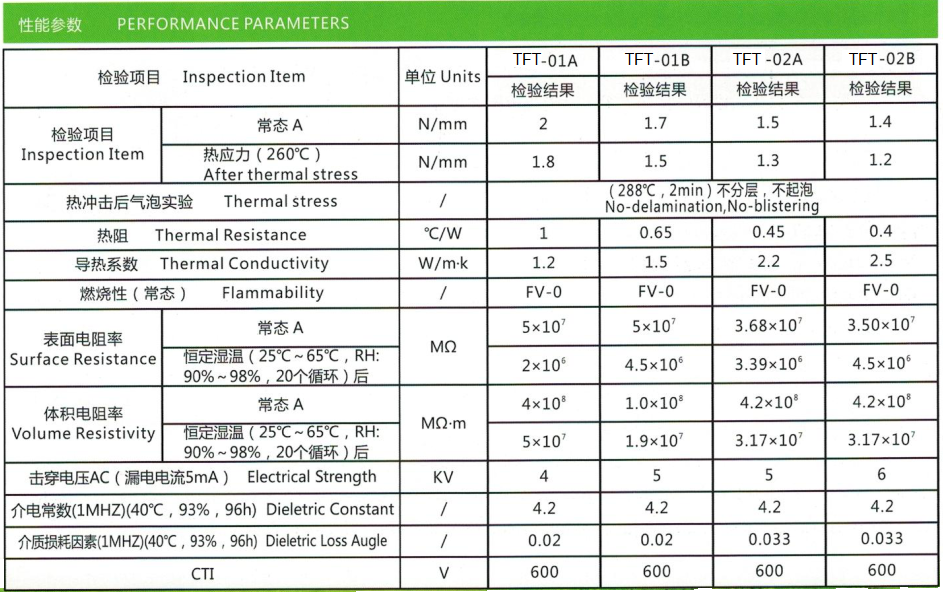

Technical Specifications

Project Technical Specifications Remarks Layers 1-2 Layers Single/Double-sided Material FR-4, Aluminum-based KB, 1060, 3003, 5052, 6061 Board Thickness 0.5, 0.8, 1.0, 1.2, 1.5, 1.6, 2.0, 3.0 (mm) Insulation Layer Thickness 75, 100, 125, 150 micron Copper Foil Thickness H 1, 2, 3, 4 oz Minimum Line Width/Spacing 0.1mm Minimum Drill Hole Diameter 0.8mm Minimum Punch Hole Diameter 2.0mm Minimum Pad 2.0mm Minimum Text Thickness 2.0mm Minimum Text Height 2.0mm Pad Surface Treatment Spray Tin, No Spray Tin, Electroless Nickel Gold, Environmentally Friendly Anti-oxidation Solder Mask Color White/Black/Green/Red Legend Color White/Black/Green/Red Insulation Resistance 10KMΩ-20MΩ Conduction Resistance <50Ω Test Voltage 300V Maximum Production Size 1500mm*600mm Tolerance Hole Diameter ±0.1mm Warping 0.7-1% Panel Size Greater than 110*100, less than 600*1500 Board Thickness Greater than 0.6mm Remaining Thickness Greater than 0.3mm Outer Dimension Tolerance Milling ±0.15mm, Punching ±0.1mm Line Width ±0.05mm Outline V-CUT ±0.1mm CNC ±0.1mm Mold Punching ±0.1mm Slot to Slot 2.0mm Slot to Line 0.5mm Circular Deviation 0.75mm Testing 100% Computer Open and Short Circuit Test Aluminum-based Copper Clad Laminate

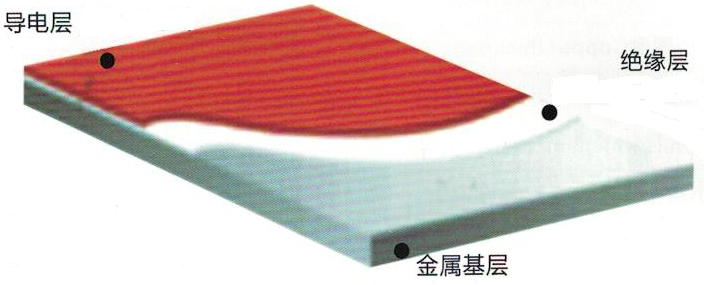

1. Product Structure ◎Conductive Layer - Made of copper foil after adhesive treatment ◎Insulation Layer - Divided into fiberglass and non-fiberglass types ◎Metal Base Layer - Aluminum plate, iron plate, stainless steel plate, copper plate

PCB aluminum-based boards consist of a circuit layer, a heat-conducting insulation layer, and a metal base layer. The circuit layer (i.e., copper foil) is usually etched to form a printed circuit, connecting the various components. Generally, the circuit layer requires a high current carrying capacity, so thicker copper foil is used, typically 35um-280um; The heat-conducting insulation layer is the core technology of PCB aluminum-based boards. It is usually composed of a special polymer filled with special ceramics, with low thermal resistance, excellent viscoelastic properties, and anti-aging ability, capable of withstanding mechanical and thermal stress. The metal base layer is the supporting component of the aluminum-based board, requiring high thermal conductivity. It is generally an aluminum-based board, but copper can also be used (copper provides better thermal conductivity), suitable for drilling, punching, and cutting. PCB materials have incomparable advantages over other materials. Suitable for surface mount technology (SMT) of power components. No heat sink is required, greatly reducing the size, good heat dissipation, good insulation and mechanical properties.

◎Features: Good heat dissipation, excellent dimensional stability, good machinability, electromagnetic wave shielding, excellent cost performance

Application Fields: LED lighting circuits, back-end hybrid integrated circuits, power supply circuits, solid-state relays

2. Product Description

The product features a flat surface, light weight, good dimensional stability, and easy processing. Especially, it has low thermal resistance and is widely used in industrial power supply equipment, automotive and motorcycle ignition devices, regulators, high-power LEDs, audio equipment, power supply modules, and other electronic and electrical devices with heat dissipation requirements. In addition, this material has good shielding performance and can be used in electrical systems requiring shielding. The product has been serialized with complete specifications. Aluminum substrate models include: TFT-01A, TFT-01B, TFT-02A, TFT-02B, etc. Aluminum substrate thicknesses include: 0.8mm, 1.0mm, 1.2mm, 1.5mm, 1.6mm, 2.0mm, 3.0mm, etc. Aluminum plate models: 1060, 3003, 5052, 6061. Copper foil thicknesses include: 35um, 70um, 105um, 140um. Panel sizes: 500X600mm, 1200X500mm, 1200X600mm, 1500X600mm.

Our Services and Advantages

1. Design circuit diagrams for customers free of charge according to customer requirements and produce customized products for customers;2. Copy and draw circuit boards for customers free of charge based on samples provided by customers, and produce products that meet the needs of the broader market for customers;3. Samples and bulk orders can be expedited to ensure customer production schedules;4. Sign confidentiality agreements with customers to ensure the uniqueness of customer products;5. Undertake PCB SMT chip mounting processing services and SMT stencil making services, providing one-stop component procurement for customers;6. Free electrical testing to ensure 100% good products;

中文版

中文版

English

English русский

русский 한국어

한국어 日本語

日本語 Español

Español Português

Português Français

Français عربي

عربي